Main units

5-axis main unit

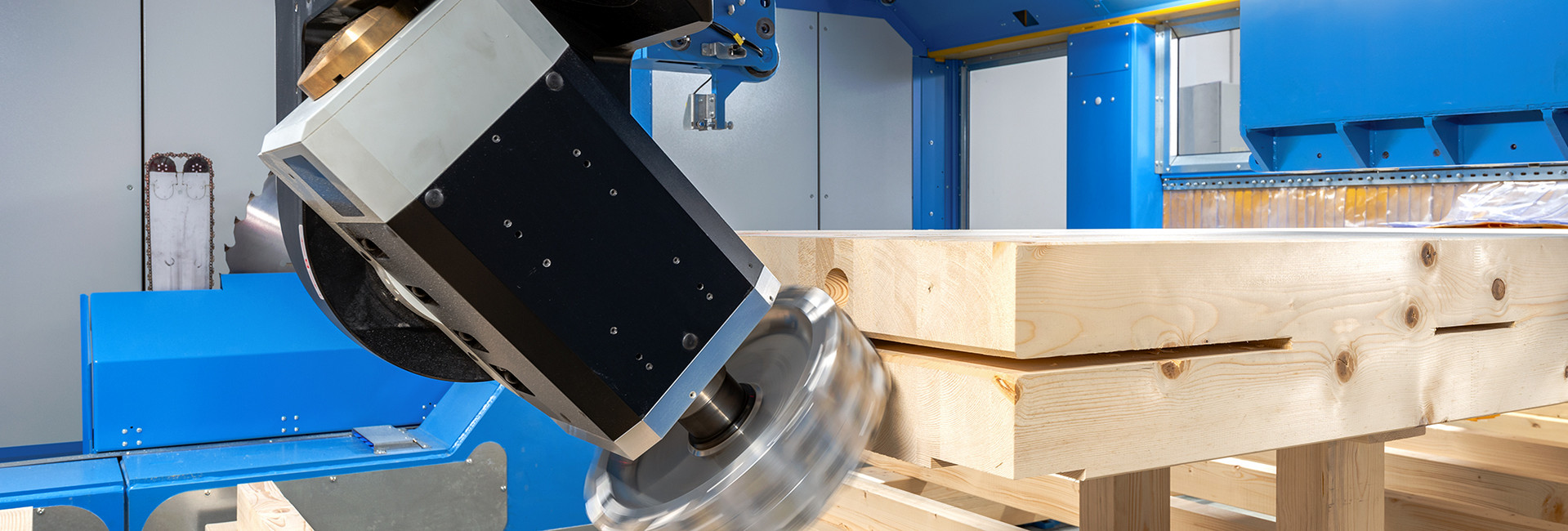

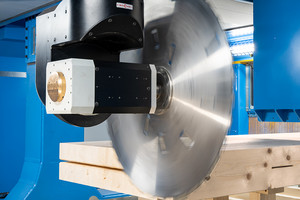

The compact and powerful spindle unit offers performance of 35 kW and continuous speed control from 0 to 12,000 rpm. This allows the optimum use of both large tools, such as saw blades, at low rotational speeds, as well as smaller end mills, which require high rotational speeds for optimal performance.

Depending on machining requirements, tools are automatically exchanged directly from the integrated tool magazine. The characteristic data of the milling and drilling tools stored in the system, such as type, diameter, length, magazine slot and optimum speed, is input automatically. This permits precise and efficient use of the tools during use.

The powerful PBA-X 5-axis unit enables a parts to be machined on all six faces in just one clamping operation. Powerful water cooling of the spindle ensures constant performance, even for intensive applications over different speed ranges, and extends the service life of the spindle and maximises machine uptime. A moving shutter system on the sides of the gantry also minimizes dust and chip emissions from the machining zone.

Tool change system

The tool magazine is a fixed part of the gantry frame and moves in sync with the machine. The tool needed for each machining operation is removed from the magazine fully automatically based on the production steps calculated in CAMBIUM®. Thanks to the independent X, Y, Z and C axes of the tool magazine storage system, all tools can also be provided for another, optional main unit. In principle, all conventional tools such as drills, end mills, side milling cutters and dovetail mills can be used. Up to 50 tool slots are available for standard tools.

The additional tool slots of the PBA-X are the perfect option.

They enable a wide variety of tools to be individually provided. The high-quality tool holders ensure fast and efficient exchange of the tools.

In addition to the basic provisioning of tools, the PBA-X can be equipped with up to three further large-tool slots. These provide space for a circular saw blade with a maximum diameter of 1,100 mm, an angled milling head with a 90° inclination and a chainsaw bar with a maximum effective length of 600 mm.