All the machine service capabilities are backed up by the in-house design and 3D modelling team who can work through the most minute details in your requirements prior to manufacture.

The process provides the client with an intricate 3D design for review and approval prior to manufacturing commencing.This saves a huge amount of time on site during the installation process in problem avoidance through forward planning.

We have a wealth of experience in building both traditional and complex structures throughout the UK but specialise in finding structural solutions to fit in with architectural design mandates.

In addition, InWood offer in house finger jointing and structural lamination across a wide variety of softwoods and hardwoods, as well as the more modern modified timbers such as Accoya.

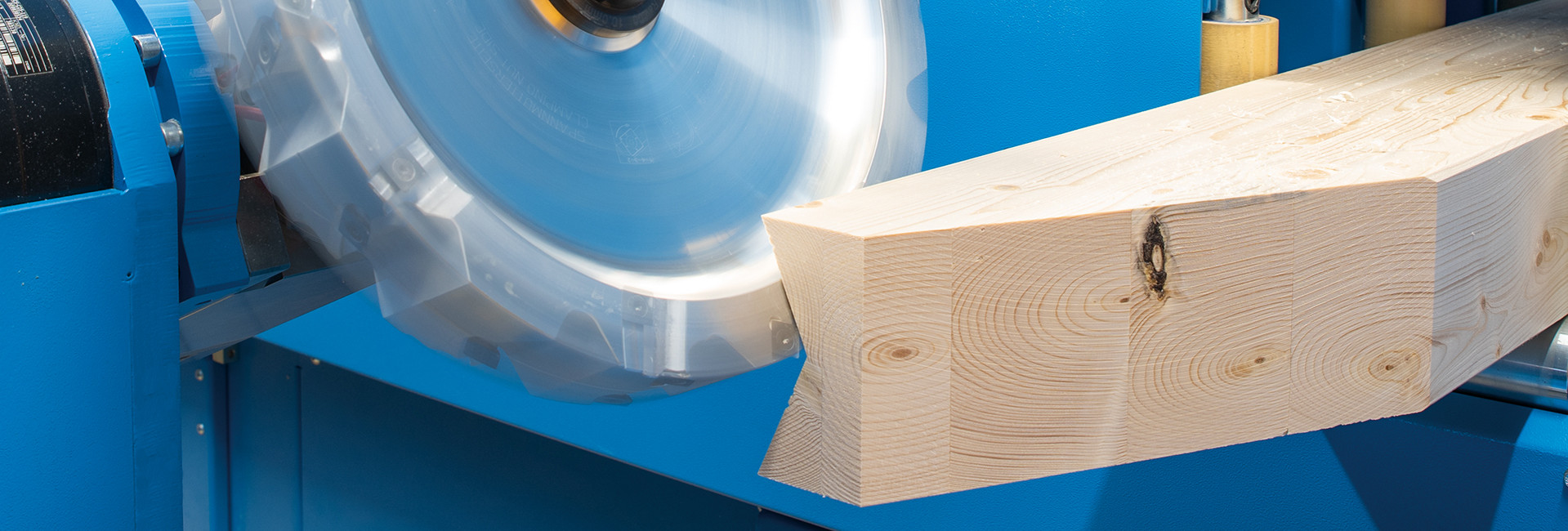

InWood manufacture our own Glulam beams, and these feature largely in our CNC product line.

With MMC growing we can design large structures under our Off-Site Manufacturing process to deliver entire buildings, engineered and manufactured to exacting tolerances through our Hundegger Robot Drive.

These buildings are fast to install, hugely energy efficient and are an excellent carbon fixing process in today’s climate conscious environment.

If you are seeking anything in the engineered timber sector reach out to one of our team at Info(at)In-Wood.co.uk

Visit for more information: www.in-wood.co.uk

More on Hundegger’s Robot Drive Machine: https://youtu.be/yt3jI7FpQ1A

timber MEDIA 11_07_2024