Small in size – big on performance!

Flexibility and performance in one compact machine.

It’s what many timber construction companies from around the world have been waiting for: Hundegger has once again added machines with modest space requirements to its product range.

The ROBOT-Compact 650 allows economical and professional joinery even for companies with limited space and small production quantities. Efficiency is achieved on the one hand through the proven use of the 6-axis robot unit of the ROBOT-Drive with automated tool changer, and on the other thanks to a sophisticated product concept.

Our main aim in development was maximum flexibility coupled with minimum use of space.

Hundegger ROBOT-Compact 650:

Professional joinery – compact and flexible

The ROBOT-Compact

- ROBOT-Compact 650

- For cross-sections from 20 x 60 mm to 300 x 650 mm - for all requirements up to the joinery of laminated girders and cross laminated timber

HIGHLIGHTS OF THE ROBOT-Compact 650

Today, efficient and profitable production is a decisive factor in the success of any company. This is precisely why the ROBOT-Compact 650 was uncompromisingly fitted with the innovative 6-axis robot unit.Automatic joinery leads to a real boost in capacity.

The simple formula for success is: Produce more parts with fewer employees and in a shorter time.

Precision and profitability cleverly combined.

The central element is the patented 6-axis robot unit with 28 tool slots.

You can use the ROBOT-Compact 650 to complete all conventional operations in a single pass, without part rotation or turning.

- Flexibility and performance compactly combined in the smallest space

- Unmatched flexibility for bespoke projects

- For cross-sections from 20 x 60 mm to 300 x 650 mm

- 6-axis technology = processing on 6 sides in a single pass

- 6-axis technology = utilization of 28 different tools

VIDEO ROBOT-Compact 650

Datapolicy | Imprint

Processing examples ROBOT-Compact 650

With a huge increase in flexibility, quality and efficiency.

PERFECT JOINERY

CAPACITY INCREASE WITH SIMULTANEOUS COST REDUCTION

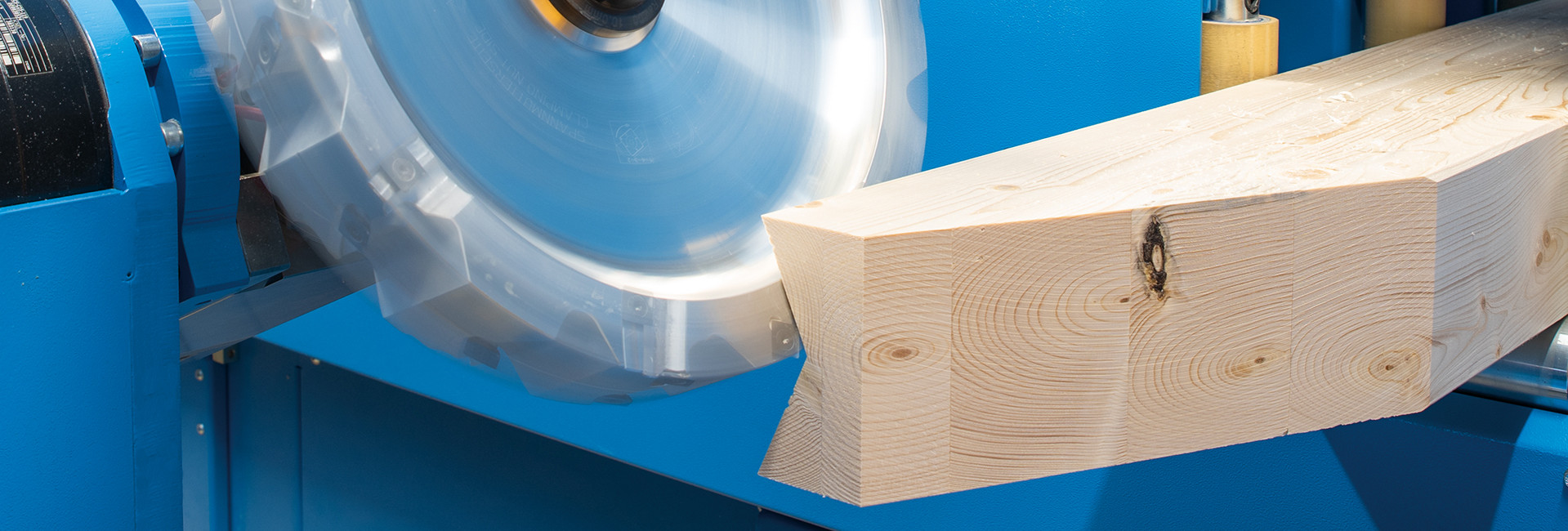

Whether carpentry joinery, timber frame construction, log house construction, half-timber house construction, glulam construction or the joining of cross laminated timber – the 6-axis robot unit with its flexible tool changer is perfectly equipped for every challenge. Trimming, grooving, drilling, milling, slotting or marking: with the right tool in the magazine, the processing possibilities are almost unlimited. The infinitely variable speed range of the ROBOT spindle in combination with different tool approach strategies and processing cycles selected according to the specific requirement ensure surfaces up to visual quality.

Modular design

For your optimal performance boost

The ROBOT-Compact layout

Compact solutions for all requirements.

Automation of the Hundegger ROBOT-Compact 650

Flexible thanks to a modular system

Automatic infeed buffer

Our automatic infeed buffer offers a further boost to productivity. The operator can place several pieces of timber at the same time on the loading cross conveyor with stainless-steel slatband chains. The system automatically feeds these pieces of timber separately to the processing zone. This allows the operator to perform other tasks.

![[Translate to English (Kanada):] [Translate to Englisch (Deutschland):] [Translate to Deutsch (Deutschland):] Schlitzgerät](/fileadmin/_processed_/a/0/csm_Schlitz_ed50c695fc.jpg)

![[Translate to English (Kanada):] [Translate to Englisch (Deutschland):] [Translate to Deutsch (Deutschland):] Bauteilausgabe](/fileadmin/_processed_/3/7/csm_Kleine_Bauteile_33b638a1e3.jpg)

![[Translate to English (Kanada):] [Translate to Englisch (Deutschland):] [Translate to Deutsch (Deutschland):] Auskehlung](/fileadmin/_processed_/7/7/csm_Auskehlung__8104129_ae944d3212.jpg)

![[Translate to English (Kanada):] [Translate to Englisch (Deutschland):] [Translate to Deutsch (Deutschland):] Steigende Kerve](/fileadmin/_processed_/2/c/csm_steigende_kerve_8108713_8c96755e44.jpg)

![[Translate to English (Kanada):] [Translate to Englisch (Deutschland):] [Translate to Deutsch (Deutschland):] Klingschrot](/fileadmin/_processed_/f/c/csm_Klingschrot_8109798_d5f0b86eb7.jpg)

![[Translate to English (Kanada):] [Translate to Englisch (Deutschland):] [Translate to Deutsch (Deutschland):] Mehrspindelbohrer](/fileadmin/_processed_/4/d/csm_Mehrspindel_Bohrer_24e3bd6d7e.jpg)

![[Translate to English (Kanada):] [Translate to Englisch (Deutschland):] [Translate to Deutsch (Deutschland):] Schlitzgerät](/fileadmin/_processed_/f/d/csm_Schlitz_8108739_d8ccd089a3.jpg)

![[Translate to English (Kanada):] [Translate to Englisch (Deutschland):] [Translate to Deutsch (Deutschland):] Profil](/fileadmin/_processed_/8/2/csm_Profil_8108727_d547e1ea7b.jpg)