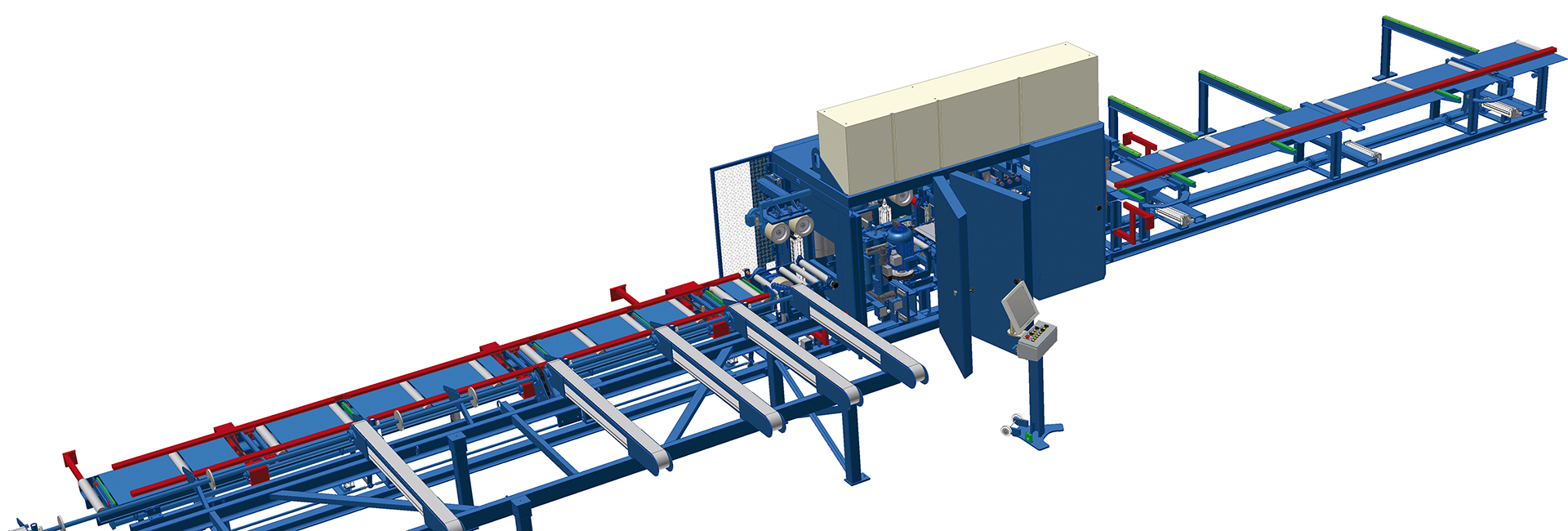

Hundegger HM-3 400

4-sided planing machines

Structural timber planing and chamfering without presetting - cross-sections up to 400 mm

The manually or automatically feedable machines plane and chamfer up to 4 part sides simultaneously in one operation. Depending on the use of the timber, the operator or a joinery program can also preselect only 1, 2 or 3 sides or partial areas. The planers have powerful feed units and planer motors to safely transport and plane even wet, warped or twisted wood. The PC-based control system automatically adjusts the feed speed according to the load on the planer motors, thus avoiding downtime. The planing machines are already equipped as standard with an infeed and outfeed roller conveyor as well as a sound insulation cabin. Extensive accessories such as cross conveyors, lifting tables or a destacking unit are available for every application.

Planer HM-3

- Planer HM-3 400 - from 20 x 50 to 300 x 400 mm - the basic machine for every carpentry business

THE HIGHLIGHTS OF THE PLANING MACHINE

Fully automatic planing and chamfering

Fully automatic planing and chamfering of structural timber - from the roof lath to the heavy purlin - without presetting and re-tooling thanks to automatic cross-section scanning, length measurement and pre-positioning of all units as well as feeds.<br/> Wood that has already been joined can therefore be planed and chamfered without problems. Thanks to the automatic conveying equipment, optionally with lifting table or destacking, only one person is required for operation, loading and removal.<br/> <br/>

Cutter replacement

Due to the centrifugal clamping system the cutter change with 4 or 2 cutters per planer head is carried out in seconds without tools or setting work.

For all requirements

TriTALL® cutters made of chrome steel, HSS cutters, solid carbide cutters and M42 cutters with hardened cutting edge and soft core are available for every requirement and wood type.

HM-3 / planing width up to 400 mm

The HM-3 has already proven its worth in practice in many companies as a robust and universal planing machine. With a machining width of 400 mm and feed speeds of up to 20 m/min, this machine type meets most requirements in carpentry or prefabricated house firms. The planing data can be transferred from Hundegger joinery machines as well as from all commercially available joinery or CAD programs or can be entered directly on the mobile control panel.

- Fully automatic thickness planing and chamfering

- Planing and chamfering with automatic cross-section measurement

- Planing sides can be selected at the display

- Planing and chamfering of part areas (front, back or front and back etc.)

- Fully automatic planing of rafter heads

- Automatic transfer of planing parameters

- Manual or automatic charging using conveyor systems

HM-3 machining examples

From the roof lath to the heavy purlin

PLANING AND CHAMFERING WITHOUT PRE-SETTING

Fully automatic thickness planing and chamfering or planing and chamfering with automatic cross-section scanning

Fully automatic planing and chamfering of structural timber - from the roof lath to the heavy purlin - without presetting and re-tooling thanks to automatic cross-section scanning, length measurement and pre-positioning of all units as well as feeds. Wood that has already been joined can therefore be planed and chamfered without problems.

Loading/soundproof cabin

Thanks to the automatic conveying equipment, optionally with lifting table or destacking, only one person is required for operation, loading and removal. Parts can be fed and discharged on both sides. The planing machines are already equipped as standard with an infeed and outfeed roller conveyor as well as a sound insulation cabin.

Convincing technology

The planing machines HM-3 have been developed for the special requirements for the planing and chamfering of structural timber.

HM-3 planer