Hundegger ROBOT-Max

The New Standard

The performance, versatility and flexibility of the ROBOT-Max combined with the power of the Hundegger Cambium software is setting a new standard in mass-timber production.

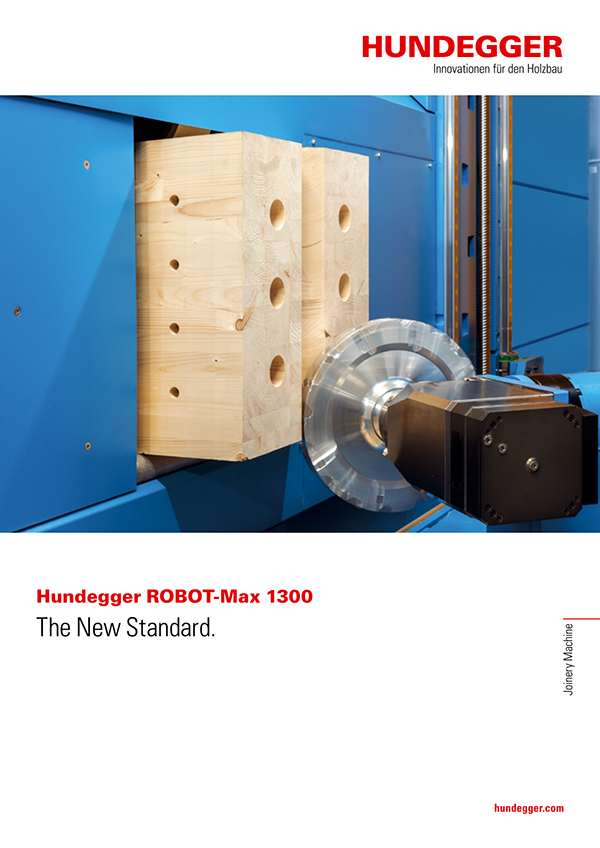

Hundegger’s ROBOT-Max expands the unlimited timber processing options of its 6-axis ROBOT-Drive by offering single-pass processing of timbers up to 610 mm x 1300 mm.

Customizable ROBOT-Max options meet the higher capacity demands a growing mass-timber industry.

The ROBOT-Max

- ROBOT-Max 1300 - from 20 x 60 to 610 x 1.300 mm - for all requirements up to the joining of laminated girders and cross laminated timber

THE HIGHLIGHTS OF THE ROBOT-Max

Maximize throughput, Maximum flexibility, Maximum cross section.

Process all 6 sides of the part in one pass – with up to 32 freely selectable tools you will never have to rotate a part again. All this in a single pass.

The Hundegger ROBOT MAX comes with a standard 29 kW - liquid cooled - variable speed from 0 to 15000 rpm engineered tough to endure industrial output for years - all processes are carried out at impressive speed.

Value creation de luxe.

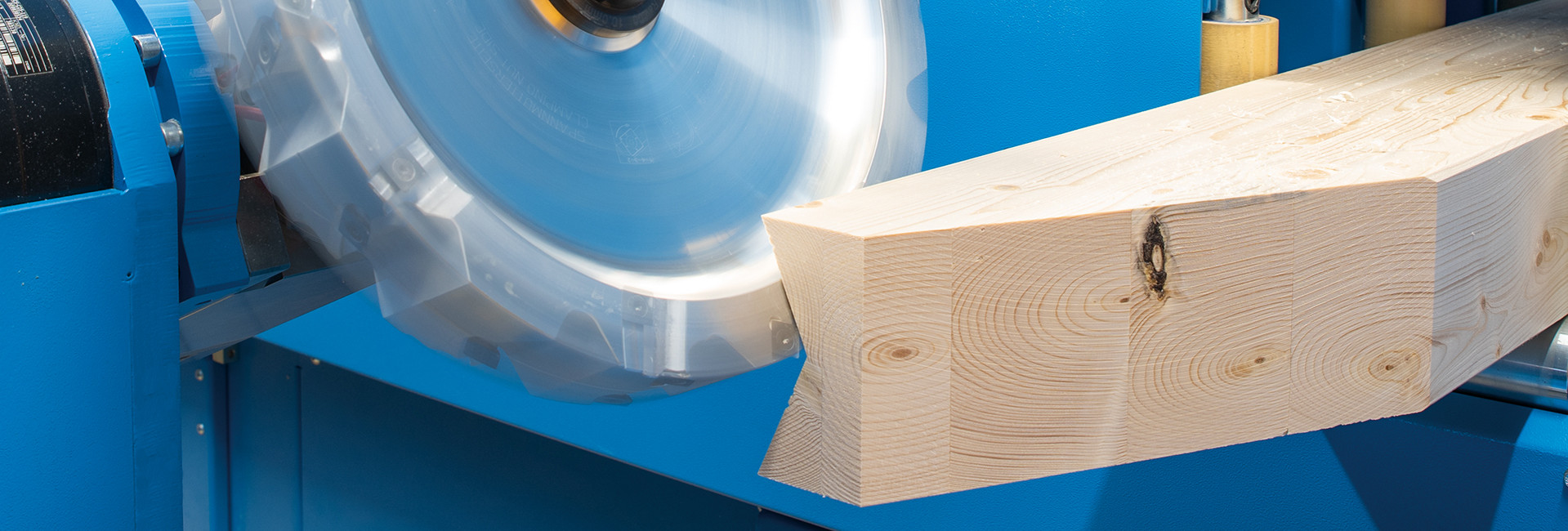

The overhead 5-axis saw/slot/marking unit with a drive rating of 13 kW further increases the throughput of the ROBOT-Max. Both units work perfectly in tandem. While the highly flexible saw is performing the processing operations, the next processing tool required is usually being positioned simultaneously at the robot unit.

- Individually customizable

- Comes with a 5-axis saw/slotting/marking unit for higher throughput

- Cross sections from 20 x 60 mm up to 610 x 1,300 mm

- 6-axis technology = processing on 6 sides in a single pass

- 6-axis technology = utilization of 32 different tools

VIDEO ROBOT-Max

VIDEO ROBOT-Max, Short Version

Processing examples ROBOT-Max

With a huge increase in flexibility, quality and efficiency.

PERFECT JOINERY

The ROBOT-Drive carries out all the usual joinery processing activities with maximum precision, even on larger part cross-sections, and all this in a single run, without the part needing to be turned over or rotated.The high individualization of the ROBOT-Max concept proves its worth every day anew, because the ROBOT-Max can be optimally adapted to new requirements, even long after purchase.

CAPACITY INCREASE WITH SIMULTANEOUS COST REDUCTION

Whether carpentry joinery, timber frame construction, log house construction, half-timber house construction, glulam construction or the joining of cross laminated timber – the 6-axis robot unit with its flexible tool changer is perfectly equipped for every challenge. Trimming, grooving, drilling, milling, slotting or marking: with the right tool in the magazine, the processing possibilities are almost unlimited. The infinitely variable speed range of the ROBOT spindle in combination with different tool approach strategies and processing cycles selected according to the specific requirement ensure surfaces up to visual quality.

SEGMENTATION AND SEPARATION MADE EASY

Fluctuations in ripping and cutting of large cross-sections is usually a major challenge for Mass Timber companies. Hundegger can consistently and efficiently get the job done with ease using the ROBOT-Max.

Two alternative processing options are available.

- End milling

Count on increased productivity with significantly more horsepower when operations require it. Using a cylindrical mill in the highest machining quality makes high quality finish when a standard blade won’t.

- Notching and Profiles

For industry-leading efficiency and exclusive optimization processing depend on Hundegger for a predictable notch or profile. Depending on the customer‘s preference we have a solution to suit any special profile needs.

The high individualization of the ROBOT-Drive concept proves its worth every day anew,

The performance, versatility and flexibility of the ROBOT-Max combined with the power of the Hundegger Cambium software is setting a new standard in mass-timber production.

Modular design

Can be individually adapted to your needs

Automation of the Hundegger ROBOT-Max

Flexible thanks to a modular system

The infeed system

The ROBOT-MAX infeed system is not only impressively fast with large components, but it it also delivers maximum performance for cross sections of different sizes. The components are automatically separated by the system and safely fed through the processing zone to the out feed deck. This frees up the operator to perform other tasks.

- Fully automatic feeding - independent of the cross section.

- Automatic alignment of even larger timber at the O-line.

Disposal of chips and waste wood

Chips and waste wood fall down into the disposal channel. From there, they are transported effectively out of the processing zone by means of a transport conveyor belt integrated in the machine outfeed.

The ROBOT-Max can be mounted with a base directly on a concrete floor. In order to reduce the loading and removal height, the disposal system is installed in a pit underneath the processing zone.