CORPORATE DEVELOPMENT

MAXIMUM CUSTOMER FOCUS AS A SUCCESS FACTOR

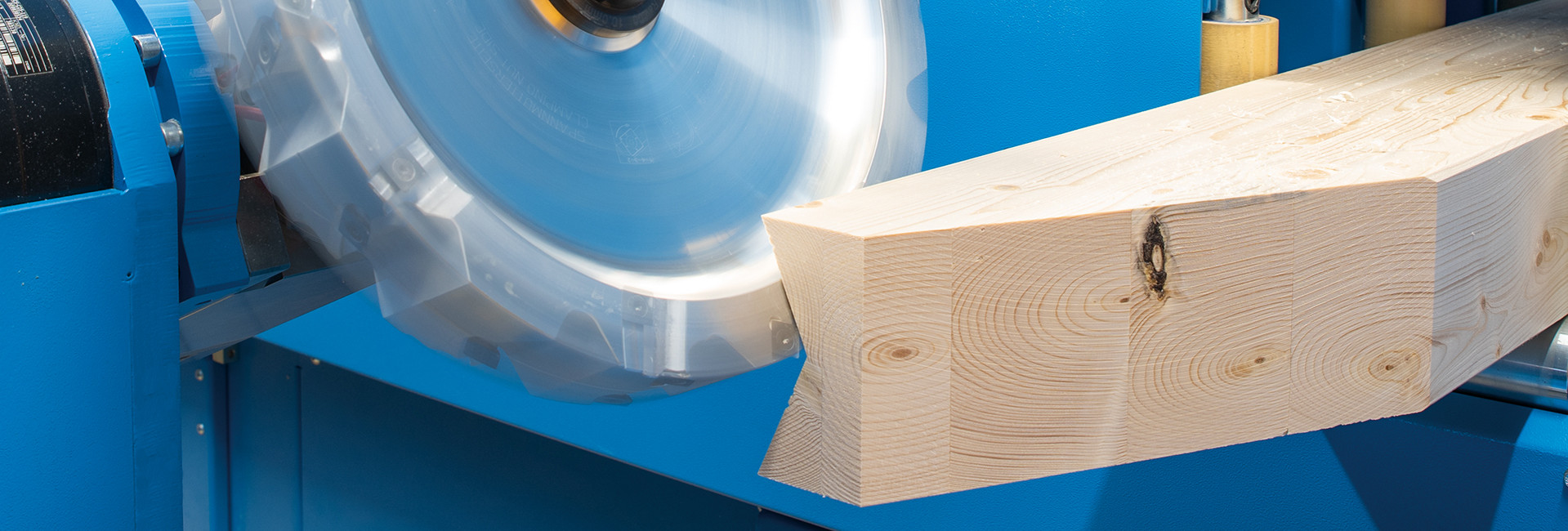

After his education in mechanical engineering, Hans Hundegger started working as a technical designer in a factory for carpentry machines. In order to make his parents’ sawmill more efficient, he began to develop and construct machines for sawmills in his spare time in the late 70s.

In 1978, he then founded his own company. In 1981, inspired by Jakob Maier, the head of a timber construction company in Türkheim, Hans Hundegger started to develop the first ever fully automatic joinery machine. This was delivered in 1985.

After a few years, the demand for fully automatic joinery machines was so enormous that at the end of 1987, the production of sawmill plants was stopped to enable the company to concentrate fully on the further development and marketing of the joinery machines.

Today Hans Hundegger AG is the world market leader in the field of CNC-controlled joinery machines with a market share of over 90%.

| 1978 | • The separate company for the development, production and marketing of sawmill plants is founded. | |

| 1981 | • Development and production of the first computer-controlled joinery machine begins. | |

1985 | • The first computer-controlled joinery machine, the P8, is delivered. | |

| 1987 | • A special 4-side structural timber planer is developed. | |

| 1988 | • The first ever automatic 4-side planing and chamfering machine for structural timber, the HMA, goes into operation. | |

| 1989 | • CAD data is transferred directly to the joinery machine for the first time. |

| 1999 | • The K2 joinery machine is showcased at the "LIGNA" fair in Hanover. At that time, it was characterized by the revolutionary | |

| 2002 | • The first MHM house is built with the Massiv-Holz-Mauer invented and patented by Hans Hundegger. | |

2003 | • Delivery of the 500th K2 joinery machine | |

| 2004 | • Delivery of the first K3 joinery machine, a high-speed variant of the K2. | |

| 2005 | • Delivery of the 100th Speed-Cut |

| 2006 | • The new automatic serial planing machine HM-4, with fully automatic tolerance monitoring during thickness planing, goes into operation. | |

| 2007 | • World premier of the latest machine generations at the "Ligna" fair in Hanover, Germany. | |

2008 | • Company’s 30th anniversary. | |

| 2009 | • The first, newly developed PWE production line for the production of profiled wood elements goes into operation | |

| 2010 | • The new K2-ROBOT is unveiled at the "Dach+Holz" fair in Cologne (Germany). |

| 2011 | • The first production line for profiled wood elements with integrated finger-jointing line is delivered. | |

| 2012 | • ROBOT-Drive, the highly flexible, compact-class joinery machine, is unveiled. | |

2013 | - • New administration building is constructed. | |

| 2014 | • Cornerstone of solid company development: | |

| 2015 | • Delivery of the 40th automatic panel processor. | |

| 2016 | • Delivery of the 1st PBA-3 gantry-type machining centre. | |

| 2017 | • Delivery of the 50th automatic panel processor. | |

| 2018 | • Delivery of the first UFA machining centre. |

| 2019 | • Construction of a new demonstration hall with a floor area of 2000 m² and additional 750 m² for training and office space. | ||

| 2019 | • Presentation of the industrial high performance class K2 Industry. | ||

2021 | • Award "Bavaria's Best 50" by the Bavarian state government. | ||

2021 |

| • Hundegger AG receives the TOP 100 label as a particularly innovative medium-sized company | |

2022 |

| • New construction of a loading and assembly hall with an office extension |