Main units

The patented 6-axis robot unit.

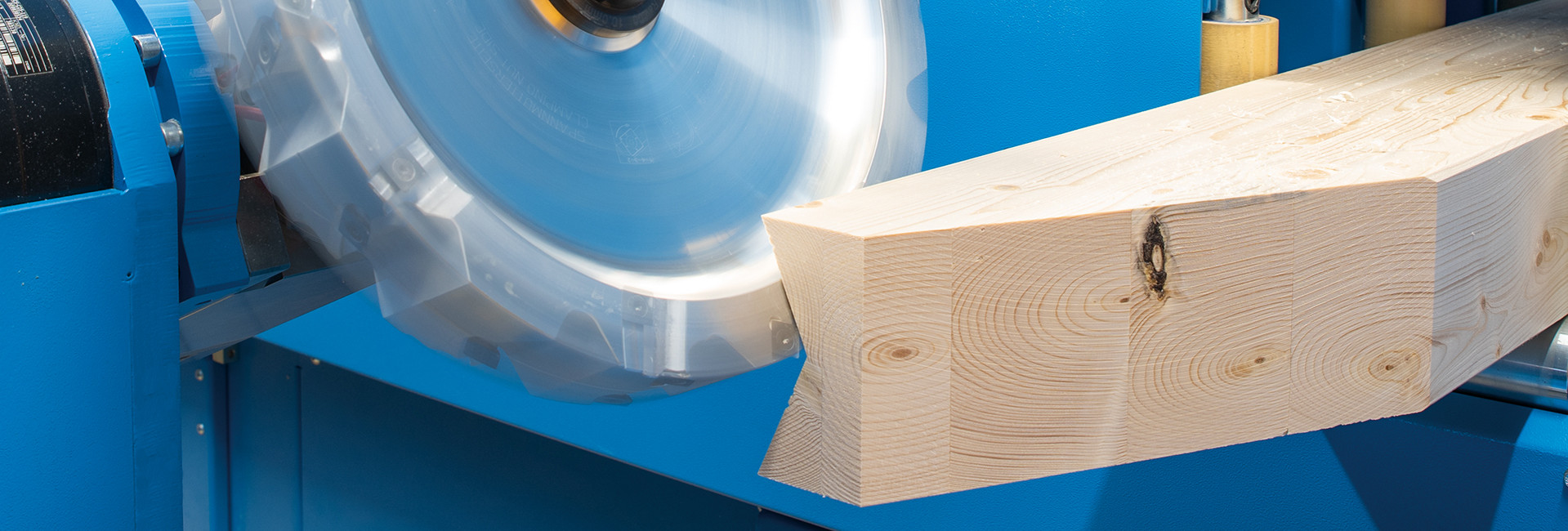

With the powerful drive of the globally proven ROBOT unit with a infinitely variable speed from 0 to 12 000 rpm, the robot unit caters to every need.

Trimming, grooving, drilling, milling, slotting and marking or labelling are the strengths of the 6-axis robot unit.Experience performance at the highest level – now also inthe tightest of spaces thanks to the ROBOT-Compact 650.

Hundegger‘s unique measuring and feed management with an intuitive, user-friendly control helps eliminateunwanted vibration and ensures that the part is always clamped in as tightly as possible delivering greater efficiency and finish quality.

The ROBOT-Compact tool magazine

The magazine of the tool changer is designed to hold up to 28 different tools with a usable length of up to 420 mm. Saw blades, drill bits, end mills, side milling cutters, dovetail mills, cylindrical mills and markers for labelling parts can be exchanged in seconds via the HSK-63-E tool holders.

Perfect tool management and selection is possible thanks to the Hundegger CAMBIUM® production program. The characteristic data of the milling and drilling tools contains not only the type, diameter, length and position in the magazine, but also the optimum speed. As a result, the program automatically selects the right tool from the magazine depending on the production requirement.